A single faulty cell in a solar panel can affect the overall output of your system — wasting both energy and money. Drone inspections make it easy to spot these issues early. They cover large areas quickly and collect thermal and high-resolution data, helping you improve performance and get the most out of your investment.

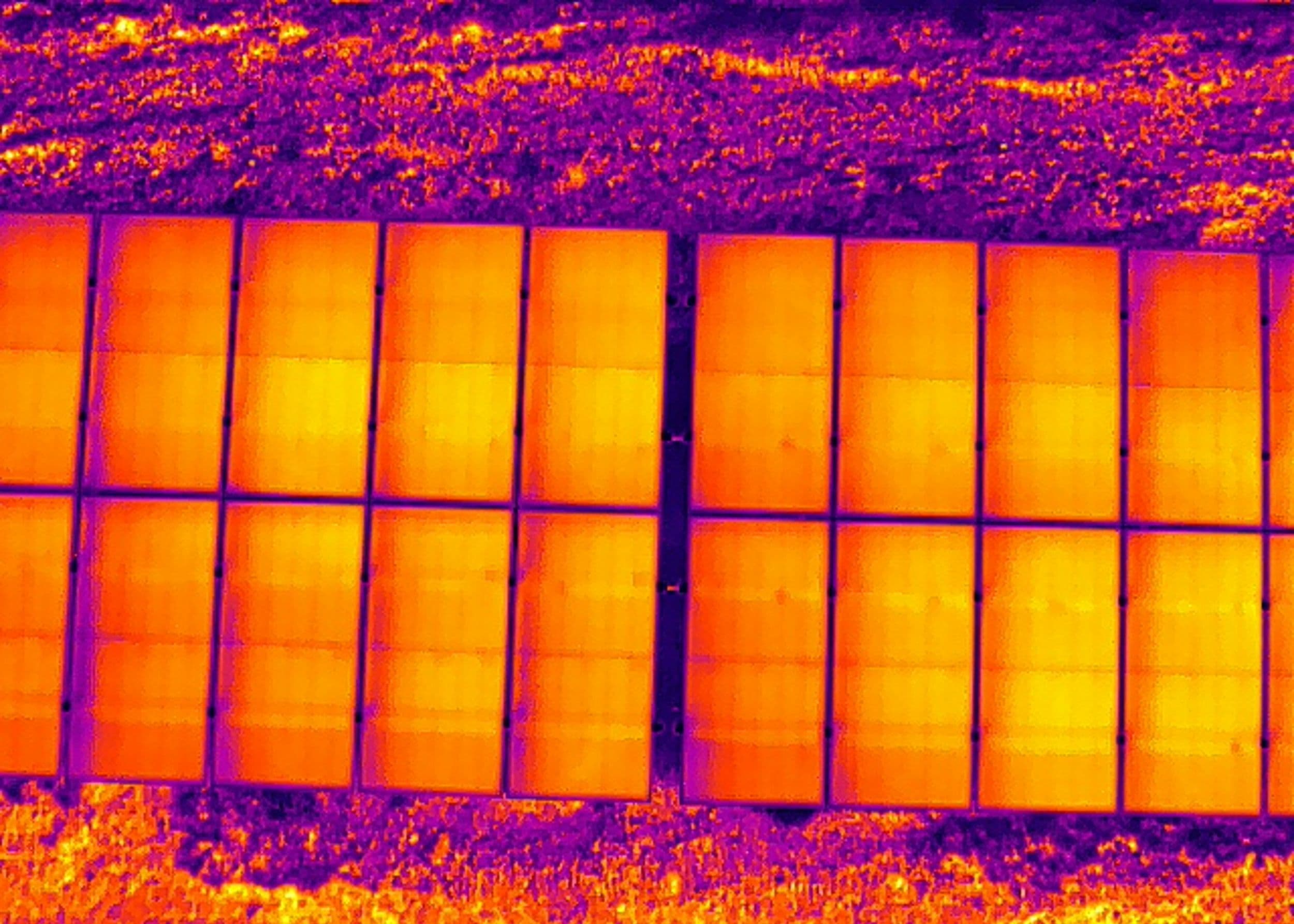

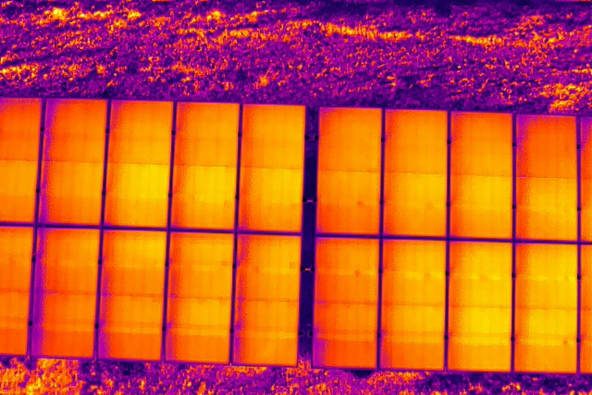

Drones equipped with thermal imaging cameras allow you to accurately assess the condition of a solar farm. Infrared photographs can be used to detect extreme temperature differences that can locate otherwise unseen issues, such as concealed moisture damage and heat leakage.

The use of drone 3D modelling technologies gives you the opportunity to inspect a digital twin of a solar farm from the comfort of your office. This detailed replica can be inspected at a minute level, allowing you to make a record of any areas that are in need of attention. Issues such as poorly executed repairs, general damage and other potential weaknesses can be shared with your employees, suppliers and other shareholders at the click of a button.

In comparison to traditional solar farm inspections, drones provide a higher degree of detail. High-definition cameras and cutting-edge zoom lenses pick up the tiny details that may otherwise go unnoticed, such as missing connections, rust, or damaged insulators, while at the same time keeping personnel safe and on the ground.

Our drones can capture the minute details of any object, without having to touch or even get close to it. Objects that once had to be shut down, climbed and traversed can now be inspected and monitored in real time more quickly, and with zero risk to personnel.

Drone inspections do not need scaffolding, equipment and other structures to be erected. This leads to less downtime and higher productivity. Complying with appropriate health and safety regulations without sacrificing production time, allows for significant financial savings.

We understand that you need answers fast. We can deliver a plain-English report with clear-cut conclusions in days. Then, you can take the steps you need to and get back to doing what you do best.

The safety of your personnel and our own is paramount, and we place it at the forefront of our company culture. Ask us about our HSSE systems and practices.

Drones capture high-quality, impartial information that gives you an exact assessment of the status and needs of your asset.

Our equipment won't touch or even go close to your assets. Our high-resolution cameras use optical zoom to give extreme close-up views while staying a safe distance away.

We use cutting-edge technologies to detect problems that would otherwise be invisible. These include 4K ultra-HD photography/video, LIDAR and thermal imaging.

Drone inspections take up less of your manhours and resources than traditional inspections, giving you a faster and more budget-friendly return on your investment.

Sometimes the brief can change even in real-time. If need be, you can be stood there right next to the drone operator, directing them as the situation develops.

Solar farm inspections can be slow and expensive. Our drones speed things up — capturing thermal and high-res data quickly, without the need for large teams on site. You get the insights you need to spot faults early, cut downtime, and keep your system performing at its best.

We collect accurate data on panel performance without sending teams up on rooftops or into the field. Early fault detection means quicker decisions, faster fixes, and fewer site visits. If panels are under warranty, we help you get replacements sorted before issues escalate — saving time and money.

The solar industry is constantly expanding. Solar panels can be expected to last 20 years. That means that maintenance and quality assurance are fundamental. A failure-free operation guarantees efficient power production, the long life of solar panels, and high ROI.

Optical zoom is a feature found in cameras that allows you to change the focal-length of the lens, which in turn magnifies the image. Unlike digital zoom, which simply enlarges the pixels of an image, optical zoom physically moves the lens elements to zoom in or out, resulting in a higher-quality, more detailed image.

Optical zoom is better than digital zoom for several reasons. Firstly, optical zoom maintains the image quality and sharpness because it captures more detail from the subject. In contrast, digital zoom often results in a pixelated, blurry image because it enlarges the existing pixels of an image, which degrades the quality.

Secondly, optical zoom allows you to get closer to your subject without physically moving closer, which can be useful in situations where you cannot or do not want to approach your subject closely. This can be especially helpful for wildlife photography or for taking photos of events from a distance.

Overall, optical zoom is a valuable feature that can help you capture high-quality, detailed images from a distance, making it a must-have for many photographers.

UHD or Ultra High Definition signifies that a camera's resolution is 3840x2160 pixels. This is exactly four time higher than high definition cameras (1920x1080 pixels), and so UHD is often also know as 4K. More about drone photography...