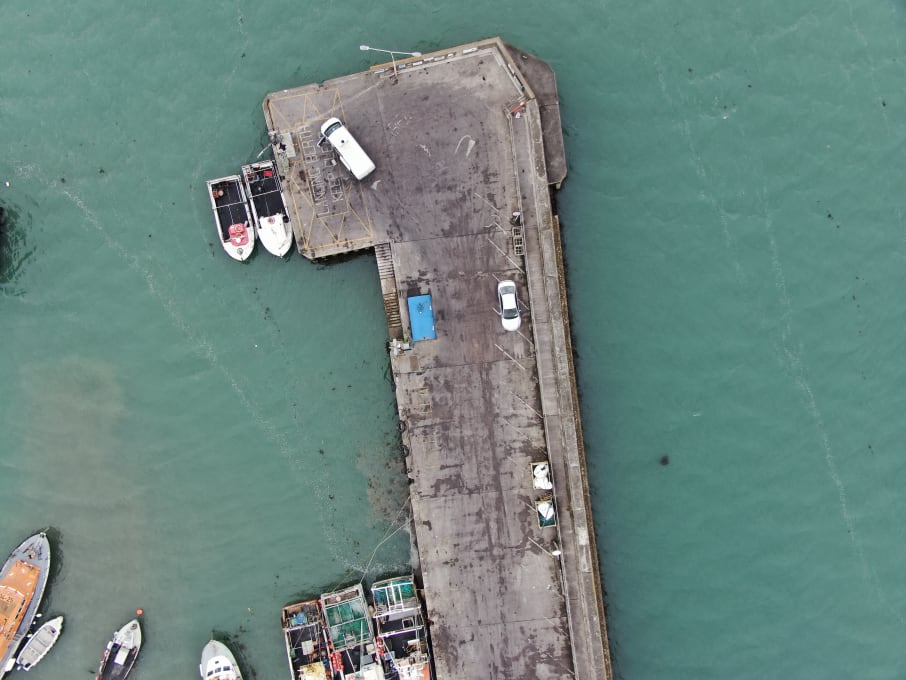

Concrete piers are critical components of waterfront structures. Over time, these piers can deteriorate due to exposure to harsh environmental conditions, leading to safety concerns and maintenance requirements. Traditional inspection methods are often time-consuming, costly, and may pose risks to personnel. In this case study, we will look at how Engineers with Drones used the latest in UAV technology for inspecting a concrete pier, showcasing their efficiency, safety, and accuracy in assessing the pier's structural integrity.

We were asked by a client to look at how we might bring value to a pier they were tasked with inspecting. The traditional method of conducting this inspection would be to send people out on boats assess to photograph the pier. They would slowly move along the length of the pier capturing data. We gave them a much more efficient option. Using a dedicated inspection drone were able to capture the entire pier in high-resolution for review back at the office. No expensive boat rental was required. The full pier was available to the team back in the office in stunning detail for a fraction of the price and time it would have taken using traditional methods.

The client was a subcontractor for a local authority. They are an extremely well established firm in the marine and coastal space and were looking for a suitable partner to help with this project. They required broad overview imagery to see the big picture of the pier. They also needed detailed imagery of every feature and defect of the pier. They also need to be easily able to identify exactly where each defect was located on the pier.

Another key requirement of the client was that all deliverables and data was to be easily accessible by all stake holders.

For this inspection, a DJI Matrice M300 RTK drone was chosen due to its stability, high-resolution high-optical zoom camera capabilities, and Real-Time Kinematic (RTK) technology for accurate georeferencing. Detailed pre-flight planning was conducted, including airspace checks, weather assessment, and obtaining necessary permissions from local authorities. The drone was equipped with a high-resolution camera capable of capturing images and videos. A flight path was designed to cover the entire surface of the concrete pier, including its vertical sides and underside where applicable. Hot rolled interlocking steel sheet pile was a major feature to be inspected as was the 386 linear meters of concrete pier wall. Images were captured at predefined intervals and angles to ensure comprehensive coverage of the entire pier.

By their nature coastal infrastructure inspections can be challenging. The environment can be tough but when you add in things like tides, swells and other variables its gets a lot worse. When you have the ability to negate all those variables while at the same time reducing the cost and then that's an opportunity you take.

Tide was a major consideration on the day. Choosing the right time to gather data while the water levels were lowest was important for getting as much data about the pier below the waterline as possible. We had a two hour tidal window in which to get all the data so we had to be efficient with our image capture plan.

We chose the DJI M300 RTK series inspection drone as the best option for this task. Coupled with the Zenmuse H20T payload with its dual wide and zoom camera s this aircraft was the perfect solution for an inspection like this. Using both the wide and optically zoomed cameras allowed us to see large sections of pier wall for orientation while also allowing us to zoom right into hairline cracks in the concrete.

Data collection itself was carried out in less than half a day. ALl the data was verified on site before being transferred to the cloud for backup. Back in the office the data was then sorted, filtered and categorised. We often say to clients that the field work is only half the job and that proper data management back in the office is a key element to a successful project. As soon as the data was processed it was uploaded to a cloud system that allowed the client and other stakeholders to access it as required.

Engineers and inspectors analyzed the imagery for signs of damage, cracks, spalling, and other structural issues. From this analysis a comprehensive report was generated, including annotated images, and defect assessment and classification. The report highlighted critical areas requiring immediate attention and provided recommendations for maintenance and repair.

The use of drones for inspecting the concrete pier yielded several advantages:

The case study demonstrates the effectiveness of using drones for inspecting a concrete pier. Drones offer a safe, efficient, and accurate means of assessing the structural integrity of critical infrastructure components. By adopting drone technology for inspections, organizations can make informed maintenance and repair decisions, ensuring the long-term safety and functionality of their assets while reducing costs and minimizing risks to personnel.

This is what the job looked like using drone technology.

What the job would have looked like if drones were not used.

You can find out more about our coastal infrastructure Inspections. Alternatively you can contact us here.

Last Updated: 30 September 2023